Productiontooling manufactured parts against the originals

Production Tooling Manufactured Parts Against the Originals is a critical inspection process that ensures components produced through tooling match the original design or master part.

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

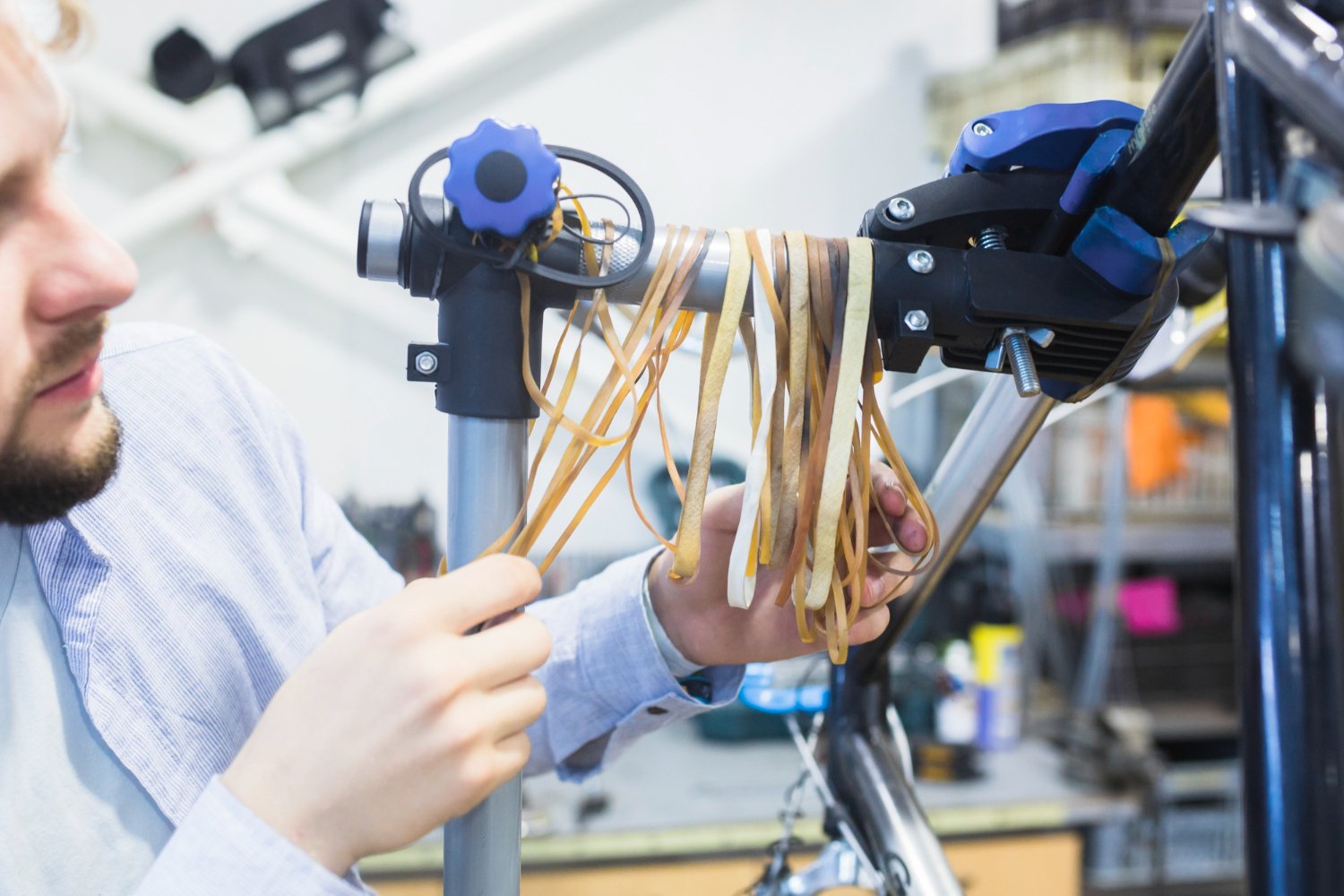

What is the Production Tooling Manufactured Parts Inspection?

This inspection process involves comparing the dimensions, shapes, and features of parts produced using tooling (molds, dies, jigs, fixtures, etc.) to the original design or a master part. It ensures that the tooling is functioning correctly and that the parts produced meet the desired quality and tolerances.

Key Features of Production Tooling Inspection

Dimensional Accuracy Verification

We measure critical dimensions of manufactured parts and compare them to the original specifications or CAD models.

Consistency in Mass Production

The inspection ensures that all parts produced from the tooling are consistent in size, shape, and quality, minimizing variability across production batches.

Tooling Wear and Deviation Analysis

Over time, tooling may wear out or deviate from the original design, leading to defects. This inspection detects these issues early, allowing for timely maintenance or adjustments.

Fit and Function Testing

The parts are evaluated to ensure they fit and function as intended when assembled with other components, maintaining the integrity of the final product.

Reverse Engineering Comparison

If original designs are unavailable, a master part is used as a reference to inspect and validate the tooling-produced components.

Our Production Tooling Inspection Process

Master Part Analysis

The original part or design is analyzed to establish the baseline measurements and tolerances for comparison.

3D Scanning and Measurement

Manufactured parts are scanned or measured using advanced tools such as Coordinate Measuring Machines (CMM) or 3D scanners.

Data Comparison

The scanned data is compared against the original part or CAD model to identify any deviations.

Deviation Reporting

Detailed reports are generated, highlighting discrepancies and providing recommendations for corrective actions.

Tooling Evaluation

If discrepancies are found, the tooling is inspected for wear, damage, or misalignment to determine the root cause.

Corrective Actions

Adjustments are made to the tooling or manufacturing process to resolve identified issues, ensuring future parts meet specifications.

Why Choose SMS Engineering for Production Tooling Inspection?

We utilize state-of-the-art tools and technologies for precise measurements and comparisons.

Our experts have extensive experience in tooling inspection and quality assurance, ensuring accurate results.

We provide detailed, easy-to-understand reports to help you make informed decisions about tooling adjustments and maintenance.

We tailor our inspection processes to your specific tooling and production requirements.

Our team works closely with you to address any issues and improve your production processes.